Optimizing DPF Maintenance – Using Diagnostic Data to Avoid Costly Replacements

Share

A Diesel Particulate Filter (DPF) can easily top $3,000 to replace, yet most premature failures are preventable. By watching the right data points on your diesel laptop, you can clean, regenerate, or service the filter long before it plugs or cracks. Below is a step-by-step framework to turn raw after-treatment numbers into an actionable DPF maintenance plan.

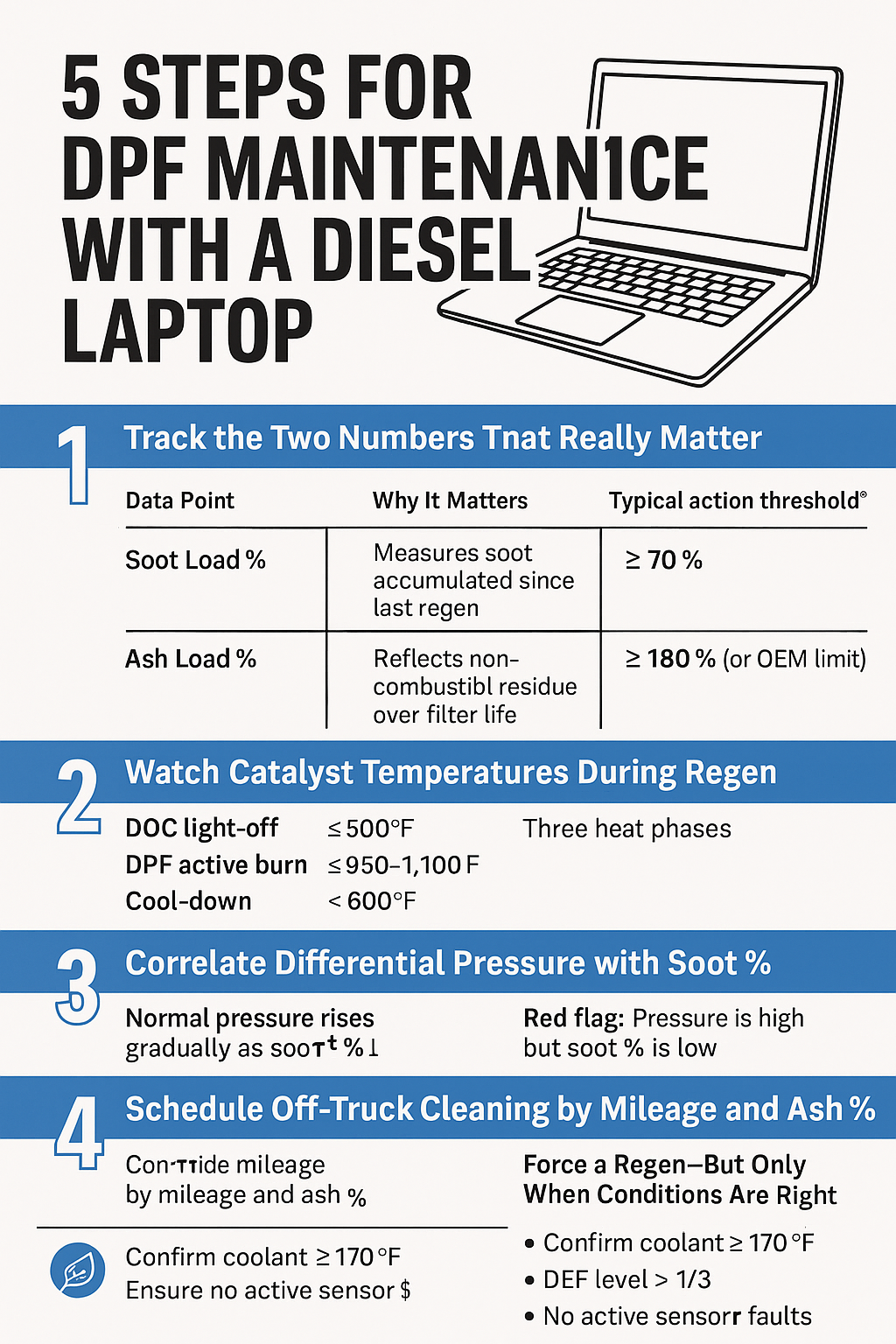

1. Track the Two Numbers That Really Matter

| Data Point | Why It Matters | Typical Action Threshold* |

|---|---|---|

| Soot Load % | Measures how much particulate has accumulated since the last regen. | ≥ 70 % → perform a parked or forced regen |

| Ash Load % | Reflects non-combustible residue that builds up over the filter’s life. | ≥ 180 % (or OEM limit) → remove & clean or replace filter |

*Always confirm thresholds with the engine’s service manual.

Diagnostic software such as Cummins Insite, OTR Diagnostics, or Universal Diag shows these two values in real time, letting you decide when to trigger regens or schedule off-truck cleaning.

2. Watch Catalyst Temperatures During Regen

A successful regen needs three heat phases:

-

DOC light-off (≈ 500 °F)

-

DPF active burn (≈ 950 – 1,100 °F)

-

Cool-down (< 600 °F)

If the DOC never exceeds light-off or the DPF plateau stalls below 900 °F, the soot won’t burn and the filter will plug again soon. Compare live temps to the above ranges every time you run a stationary regen.

3. Correlate Differential Pressure With Soot %

-

Normal trend: pressure rises gradually as soot % climbs.

-

Red flag: pressure is high but soot % is still low.

-

Possible cracked substrate, melted face-plug, or bad pressure sensor.

-

-

Opposite red flag: soot % high yet pressure barely moves.

-

Likely failed pressure sensor or kinked sense line.

-

Logging both numbers side-by-side after every service stops you from masking a mechanical failure by just resetting the soot counter.

4. Schedule Off-Truck Cleaning by Mileage and Ash %

Many fleets still pull filters only on mileage (e.g., every 250 k mi). Real-world ash accumulation varies with idle time, engine oil quality, and duty cycle. Combining mileage plus Ash % means you clean only when necessary—saving labor—while never overrunning the substrate and risking a $3k replacement.

5. Force a Regen—But Only When Conditions Are Right

Before commanding a manual regen:

-

Verify coolant ≥ 170 °F and DEF level > ⅓.

-

Confirm no active FMI 3/4/5 (voltage or circuit) sensor faults.

-

Check that soot % is over the engine’s “regen request” threshold (typically 30-50 %).

Running a regen with a cold engine or unresolved sensor faults often fails and can raise exhaust temps without actually lowering soot.

Tools Required

-

Diesel laptop (with software that displays soot %, ash %, differential pressure, and exhaust temps)

Final Takeaway

Monitoring soot %, ash %, differential pressure, and catalyst temperatures—then acting on those numbers—turns DPF maintenance from guesswork into a predictable, affordable routine. Use your diesel laptop after every service or long haul to log these values; doing so routinely can extend filter life well past the OEM replacement interval and keep expensive downtime off your balance sheet.