How to Recognize a Failing Turbocharger in Your Semi‑Truck

Share

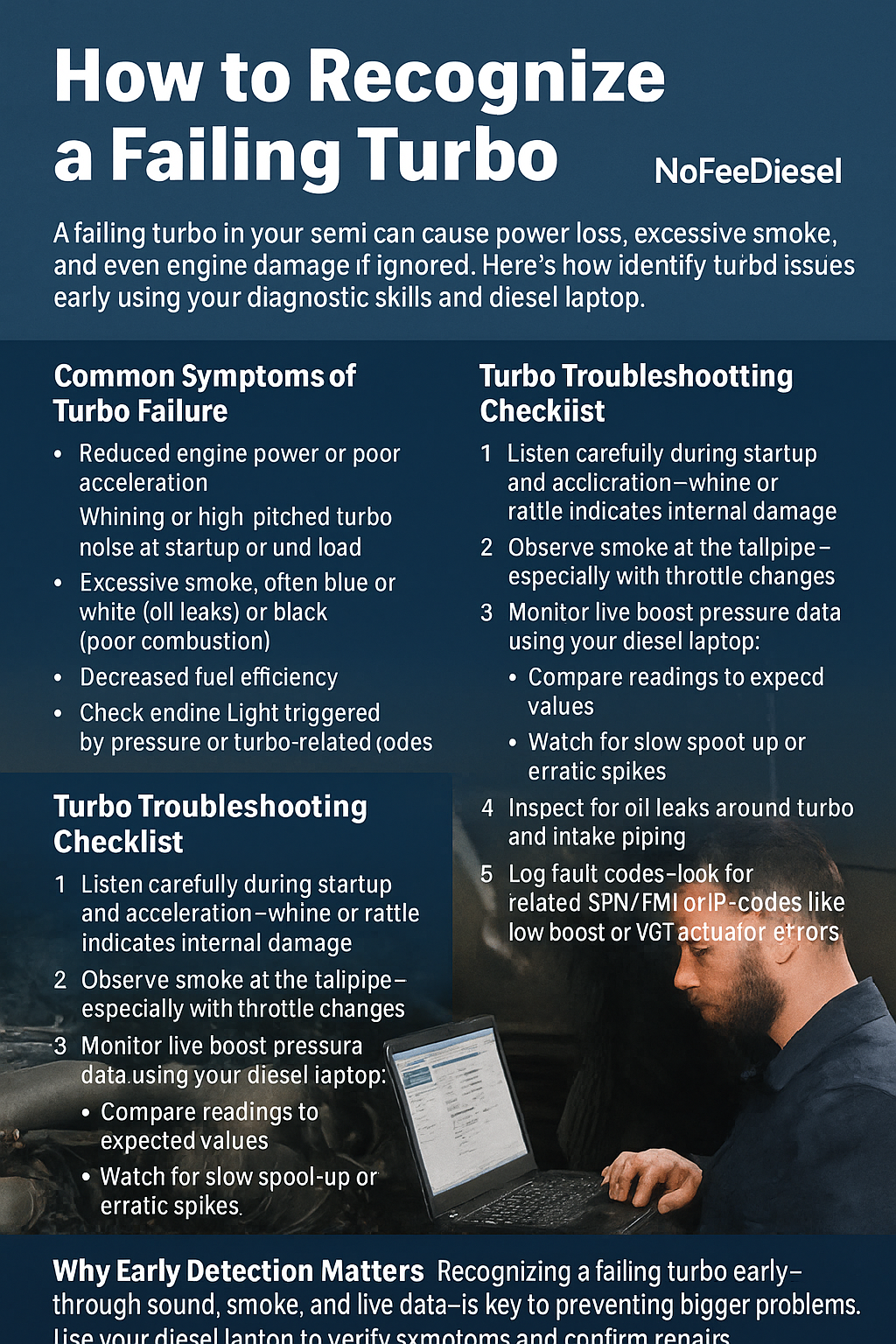

A failing turbo in your semi can cause power loss, excessive smoke, and even engine damage if ignored. Here’s how to identify turbo issues early using your diagnostic skills and diesel laptop.

Common Symptoms of Turbo Failure

-

Reduced engine power or poor acceleration

-

Whining or high-pitched turbo noise at startup or under load

-

Excessive smoke, often blue or white (oil leaks) or black (poor combustion)

-

Decreased fuel efficiency

-

Check Engine Light triggered by pressure or turbo-related codes

Typical Turbocharger Failure Causes

-

Oil supply contamination or restriction—dirty or blocked oil can damage turbo bearings

-

Extreme heat exposure, leading to warped or cracked housing and seals

-

Normal wear & tear from heavy use—especially on high-mileage trucks (500,000+ miles)

Turbo Troubleshooting Checklist

-

Listen carefully during startup and acceleration—whine or rattle indicates internal damage

-

Observe smoke at the tailpipe—especially with throttle changes

-

Monitor live boost pressure data using your diesel laptop:

-

Compare readings to expected values

-

Watch for slow spool-up or erratic spikes

-

-

Inspect for oil leaks around turbo and intake piping

-

Log fault codes—look for related SPN/FMI or P-codes like low boost or VGT actuator errors

Why Early Detection Matters

-

Catch minor issues before they worsen, preventing engine failure

-

Save on repair costs by swapping parts early

-

Maintain fuel efficiency and power output

Tool Required

-

Diesel laptop for live boost data and diagnostic code reading

Final Takeaway

Recognizing a failing turbo early—through sound, smoke, and live data—is key to preventing bigger problems. Use your diesel laptop to verify symptoms and confirm repairs. Acting quickly will protect your investment and keep your truck running clean.