Aftertreatment Diagnostics for CAT Diesel Engines: What You Need to Know

Share

When it comes to emissions compliance and performance, the aftertreatment system on your CAT diesel engine is one of the most critical — and complex — areas to monitor. Understanding how to diagnose, monitor, and maintain your DPF, SCR, and EGR systems can save you from costly downtime and protect your engine from premature failure.

In this guide, we’ll break down what aftertreatment diagnostics involve, what to look for, and how to access this information using a diesel diagnostic laptop and adapter — no subscriptions required.

What Is an Aftertreatment System?

Aftertreatment systems in Caterpillar engines typically include:

-

DPF (Diesel Particulate Filter) – Captures and stores soot from the exhaust

-

SCR (Selective Catalytic Reduction) – Reduces NOx emissions by injecting DEF

-

EGR (Exhaust Gas Recirculation) – Re-circulates exhaust gases to lower combustion temps

-

Sensors and Modules – Monitor pressure, temperature, NOx, DEF flow, and more

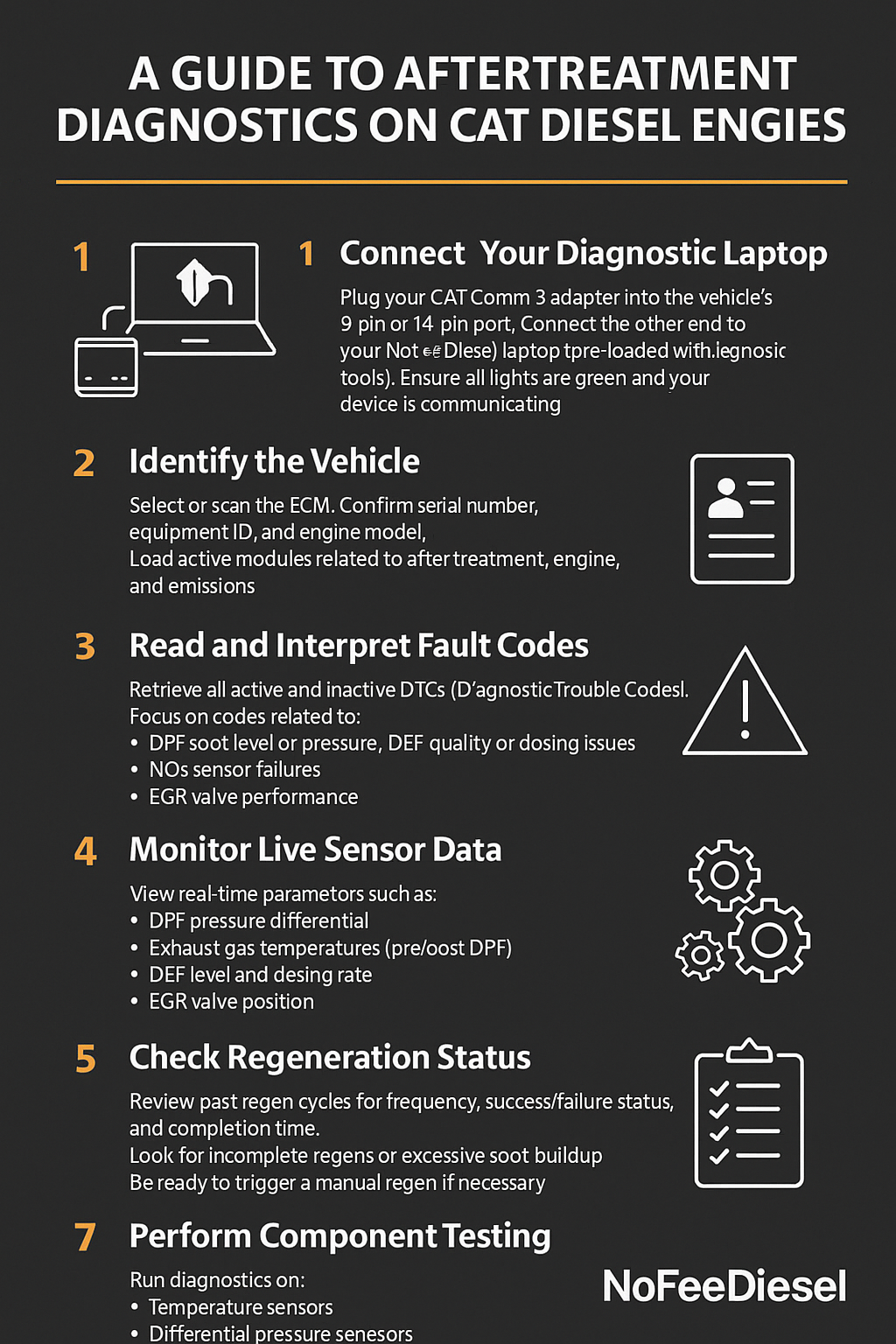

Step-by-Step: How to Perform Aftertreatment Diagnostics on CAT Diesel Engines

1. Connect Your Diagnostic Laptop

-

Plug your CAT Comm 3 adapter into the vehicle’s 9-pin or 14-pin port

-

Connect the other end to your NoFeeDiesel laptop (pre-loaded with diagnostic tools)

-

Ensure all lights are green and your device is communicating

2. Identify the Vehicle

-

Select or scan the ECM

-

Confirm serial number, equipment ID, and engine model

-

Load active modules related to aftertreatment, engine, and emissions

3. Read and Interpret Fault Codes

-

Retrieve all active and inactive DTCs (Diagnostic Trouble Codes)

-

Focus on codes related to:

-

DPF soot level or pressure

-

DEF quality or dosing issues

-

NOx sensor failures

-

EGR valve performance

-

4. Monitor Live Sensor Data

-

View real-time parameters such as:

-

DPF pressure differential

-

Exhaust gas temperatures (pre/post DPF)

-

DEF level and dosing rate

-

EGR valve position

-

NOx inlet and outlet readings

-

This data is crucial to confirming whether the system is working — or if regen or component failure is imminent.

5. Check Regeneration Status

-

Review past regen cycles for frequency, success/failure status, and completion time

-

Look for incomplete regens or excessive soot buildup

-

Be ready to trigger a manual regen if necessary

6. Test and Validate SCR & EGR Systems

-

Confirm SCR dosing via real-time data

-

Watch for irregularities in NOx reduction

-

Test EGR valve function and cooler efficiency

-

Assess system response during acceleration and deceleration

7. Perform Component Testing

-

Run diagnostics on:

-

Temperature sensors

-

Differential pressure sensors

-

DEF pump and dosing valves

-

EGR actuators and solenoids

-

Replace any components showing inconsistent data or test failure results.

Documentation Is Key

After every diagnostic session:

-

Save your reports

-

Log fault codes found and cleared

-

Track regen history and any manual actions taken

-

Maintain service history for compliance and warranty protection

All this can be done through your NoFeeDiesel diagnostic laptop, with software that stores your data locally — no cloud accounts or licensing portals required.

What Tools Do You Need?

To perform CAT diesel aftertreatment diagnostics, you’ll need:

-

A rugged diagnostic laptop

-

A CAT Comm 3 adapter

-

Pre-installed dealer-level software

-

No internet requirement, no activation codes, and no subscriptions