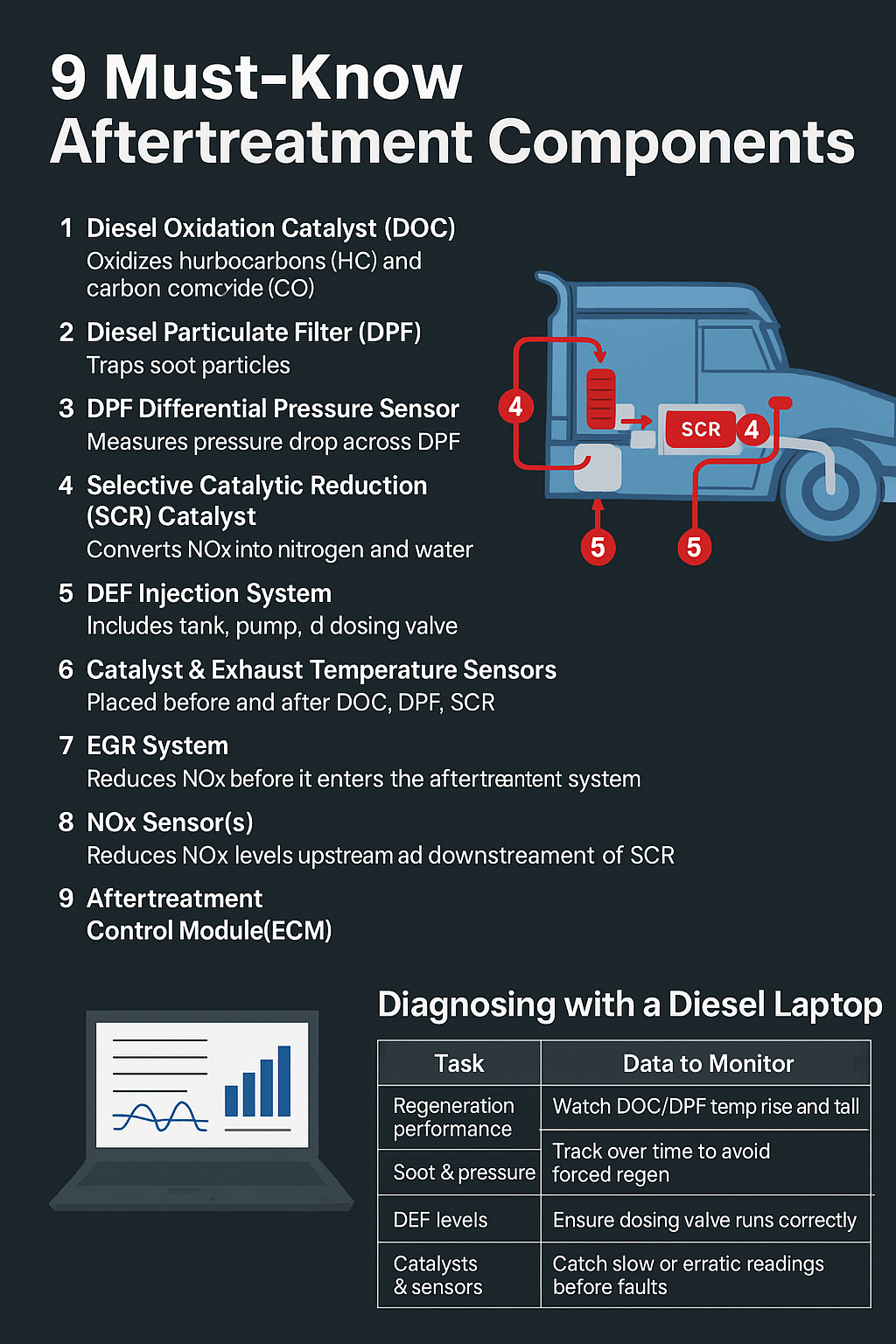

9 Must-Know Aftertreatment Components on Heavy-Duty Trucks

Share

Understanding aftertreatment systems is essential for techs and drivers aiming to prevent emissions failures. Here are the nine key components every operator should know—and how to use your diesel laptop to monitor their health.

1. Diesel Oxidation Catalyst (DOC)

Oxidizes hydrocarbons (HC) and carbon monoxide (CO) upstream of the DPF. Essential for initiating passive soot burn-off

2. Diesel Particulate Filter (DPF)

Traps soot particles. Requires periodic regeneration—passive during normal driving, active at higher temps, or forced via tool control

3. DPF Differential Pressure Sensor

Measures pressure drop across the DPF. High differential pressure indicates clogging; helps you time regenerations before serious issues occur

4. Selective Catalytic Reduction (SCR) Catalyst

Uses DEF to convert NOx into nitrogen and water—critical for emissions compliance. Utilizes urea-based reductant dosing

5. DEF Injection System

Includes tank, pump, dosing valve (also called Decomp or DeNOx unit). Reliable DEF delivery is essential—monitor dosing and tank temperature to prevent intermittent issues .

6. Catalyst & Exhaust Temperature Sensors

Placed before and after DOC, DPF, and SCR. They ensure optimal regeneration and NOx conversion. Watch for sensors that read out of range .

7. EGR System

Though technically upstream, the Exhaust Gas Recirculation cooler and valve reduce NOx before it hits the aftertreatment system

8. NOx Sensor(s)

Detect NOx levels upstream and downstream of the SCR. Used for dosing control and monitoring catalyst efficiency .

9. Aftertreatment Control Module (ECM)

Gathering data from all sensors, the ECM controls regen events, DEF dosing, and manages fault logic. Live data is your window into system health.

🔍 Diagnosing with a Diesel Laptop

| Task | Data to Monitor |

|---|---|

| Regeneration performance | Watch DOC/DPF temp rise and fall |

| Soot & pressure | Track over time to avoid forced regen |

| DEF levels | Ensure dosing valve runs correctly |

| Catalysts & sensors | Catch slow or erratic readings before faults |

A diesel laptop lets you:

-

View live soot %, ash %, pressure, temps, and NOx readings

-

Log data trends to predict issues before they fail

-

Force regens or clear counters with tool commands

Final Takeaway

Monitoring these nine aftertreatment components prevents emissions non-compliance, engine derates, and costly part replacements. Regular checks with a diesel laptop transform reactive maintenance into proactive care—saving time, money, and downtime.