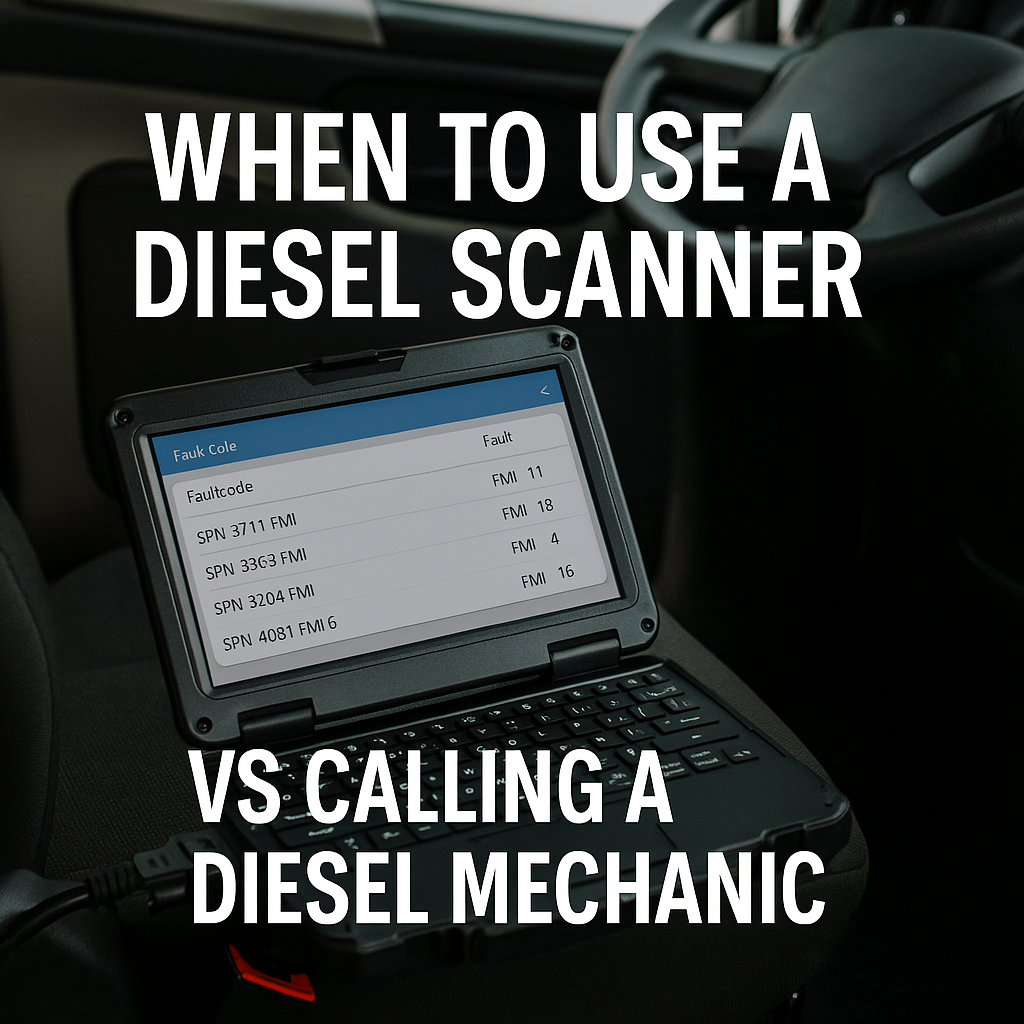

When to Use a Diesel Scanner vs. Calling a Diesel Mechanic

Share

Maintaining a diesel truck or heavy equipment means balancing two key resources: your own diagnostic tools and a professional diesel mechanic. While both are critical, knowing when to use a diesel diagnostic scanner versus when to bring in a technician can save you time, money, and prevent unnecessary downtime.

Here’s how to decide which path to take — and when your NoFeeDiesel diagnostic kit is all you need.

When to Call a Diesel Mechanic

1. Major Mechanical Repairs

If you're facing engine overhauls, fuel injector replacements, or transmission rebuilds, these repairs typically require advanced tools and physical teardown — the domain of experienced diesel techs.

2. Hands-On Inspections

Some issues — like coolant leaks, belt wear, or mechanical knock — need a trained eye. Diesel mechanics can identify physical failures that no scanner can catch.

3. Custom Fabrication & Performance Work

For jobs like turbo upgrades, performance tuning, or custom exhaust mods, you’ll want a shop with fabrication tools and dyno testing capabilities.

4. Safety-Critical Systems

Brakes, steering, suspension, and structural components impact safety. These areas require certified expertise and physical inspections, not just digital diagnostics.

When to Use a Diesel Diagnostic Scanner (Like NoFeeDiesel)

1. Electronic & Sensor Diagnostics

Modern diesel trucks rely on complex onboard computers. A diesel scanner lets you:

-

Pull engine, transmission, and ABS codes

-

Read live sensor data

-

Diagnose DEF, EGR, DPF, VGT, and injector faults

-

Run KOEO, KOER, and functional tests

You’ll know exactly what the truck is telling you — with no need to visit the dealer.

2. Routine Maintenance

Use your diesel laptop to:

-

Reset service intervals

-

Clear maintenance codes

-

Monitor DPF load and soot levels

-

Perform forced regens and DEF tests

Prevent breakdowns before they happen by staying ahead of scheduled maintenance.

3. Cut Costs and Downtime

With a NoFeeDiesel kit, you eliminate:

-

$150–$400 diagnostic fees

-

Unnecessary trips to the dealer

-

Hours wasted waiting on techs

Get clear diagnostics up front so you or your mechanic can focus only on the real problem.

4. DIY Diesel Enthusiasts

You don’t have to be a certified mechanic to use a diesel scanner. Our systems are built for:

-

Fleet owners

-

Mobile techs

-

Owner-operators

-

DIYers looking to learn and save

The Bottom Line

Think of a diesel diagnostic laptop as your first line of defense.

-

If it’s a code, regen, sensor, or calibration issue, your NoFeeDiesel scanner can handle it — right in your shop or driveway.

-

If it’s a physical failure, major repair, or safety concern, that’s when you bring in a professional.

By using both tools wisely, you’ll save money, reduce downtime, and stay one step ahead of costly breakdowns.