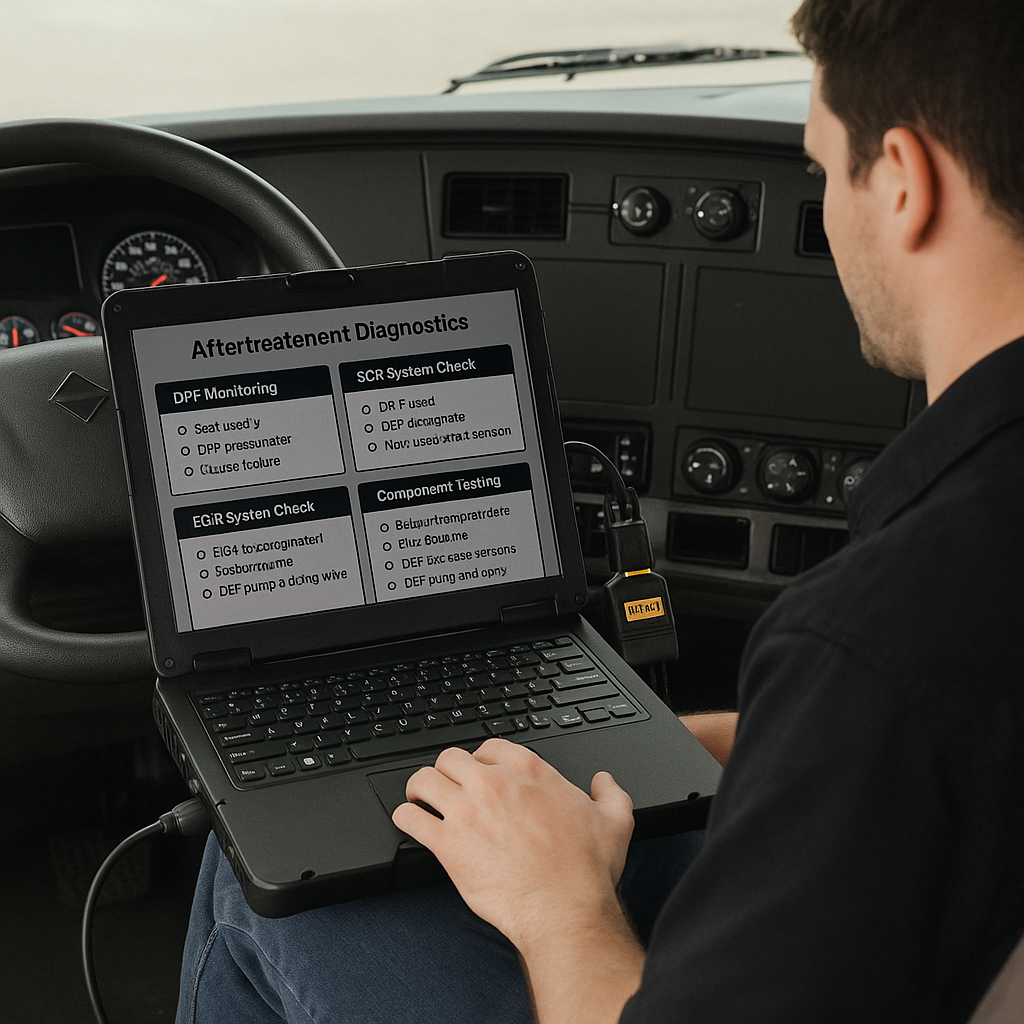

Detroit Diesel Aftertreatment Diagnostics — What You Need to Know

Share

Modern Detroit Diesel engines are equipped with advanced aftertreatment systems designed to meet strict emissions standards. These include the Diesel Particulate Filter (DPF), Selective Catalytic Reduction (SCR) system, and Exhaust Gas Recirculation (EGR) — each relying on accurate sensor data and proper operation.

When something goes wrong, it’s critical to catch the issue early to avoid derates, expensive repairs, or non-compliance. With a NoFeeDiesel laptop and RP1210 adapter, you can perform full aftertreatment diagnostics in-house — no dealer visit required.

What’s Included in a Detroit Aftertreatment System?

Your aftertreatment system typically includes:

-

DPF (Diesel Particulate Filter) – Traps and stores soot from the exhaust

-

SCR (Selective Catalytic Reduction) – Injects DEF to reduce NOx emissions

-

EGR (Exhaust Gas Recirculation) – Lowers combustion temperature to cut emissions

-

Sensors and actuators – Monitor and manage temperature, pressure, flow, and NOx levels

Step-by-Step: How to Perform Aftertreatment Diagnostics

1. Connect Your Diagnostic Setup

-

Use your NoFeeDiesel diagnostic laptop

-

Connect an RP1210-compatible adapter (e.g., Nexiq or DG Tech) to the truck’s diagnostic port

-

Ensure all connections are secure and active

2. Load the Vehicle ECM

-

Launch your diagnostic software

-

Detect and load the engine control module (ECM)

-

Confirm vehicle details like VIN, model, and control system version

3. Scan for Fault Codes

-

Read all active and inactive fault codes

-

Focus on codes related to:

-

Soot accumulation

-

DEF dosing errors

-

SCR efficiency faults

-

EGR valve position or cooler inefficiency

-

Clearing inactive codes is fine, but never ignore active faults — many can prevent regens or trigger derates.

What to Analyze in the Aftertreatment System

DPF Monitoring

-

Check soot load % and DPF pressure differentials

-

View regeneration history (frequency, success/failure, duration)

-

Identify signs of incomplete regens or blocked filters

-

Initiate a forced regen if needed

SCR System Check

-

Monitor:

-

DEF level

-

DEF dosing rate

-

NOx inlet/outlet sensor data

-

-

Confirm proper dosing and sensor response under load

EGR System Inspection

-

Verify EGR valve position and response

-

Evaluate cooler efficiency using temperature differentials

-

Identify restrictions or stuck valves that may affect combustion and emissions

Component Testing

-

Test:

-

Exhaust temp sensors

-

NOx sensors

-

DPF pressure sensors

-

DEF pump and dosing valve

-

-

Confirm they respond within proper ranges using live data

Documentation and Reporting

Every diagnostic session should include:

-

Fault codes found and cleared

-

Sensor data screenshots or logs

-

Regen status before and after

-

Notes on components tested or replaced

-

Post-repair verification

Your NoFeeDiesel laptop allows you to save, export, or print reports for service history and warranty documentation.

Why It Matters

Neglecting proper aftertreatment diagnostics can lead to:

-

Failed regen cycles

-

Engine derates or shutdowns

-

Expensive part replacements

-

Failed DOT inspections

With the right diagnostic tools, you can stay ahead of failures — and keep your Detroit Diesel engine compliant and efficient.

What You Need:

-

Rugged laptop with dealer-level software

-

RP1210 adapter (e.g., Nexiq USB-Link or DG Tech)

-

No subscription or internet activation

-

30-day satisfaction guarantee with U.S. support